MAXMETAL – SOLAR PANEL MOUNTS

Certified & Reliable

The MAXMETAL photovoltaic support bases (mounts) represent certified and reliable solutions for the installation of photovoltaic panels. We manufacture both double pole solar mounting structure and single pole mounting structure at the most competitive prices in the market, tailored to the needs of each project.

*It only takes a minute

High Quality

MAXMETAL photovoltaic support bases (mounts) are made of high-quality and durable steel, grade S235-S320 Z275 and DX51D Z275 pre-galvanized, Magnelis, or hot-dip galvanized after processing, according to the requirements and specifications of the project. The frames of the bases consist of 3 types of pieces with different sections:

- Ground-inserted anchors (with Pull Out test). Depending on the soil characteristics, the length of the anchors and the depth of insertion are selected (commonly 1.30 or 1.50m).

- Pieces of the main structure (inclined beam, brackets). There is flexibility in the length of the inclined beams depending on the length of the panels.

- Special section crosspieces on which the panels are held.

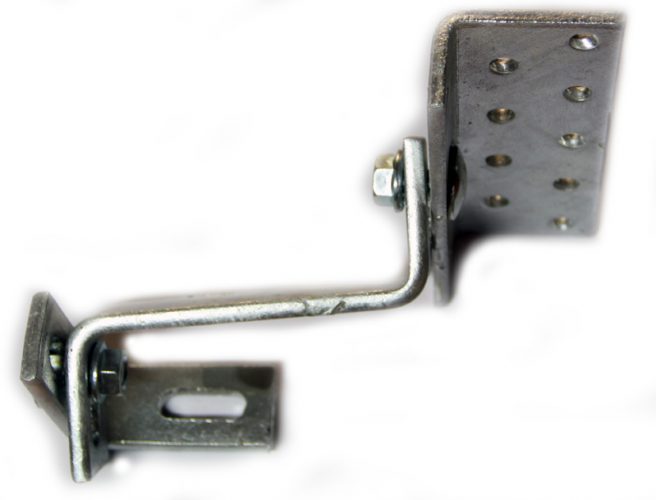

Intermediate and terminal supports (clamps) can securely hold all types and thicknesses of panels on the market. There are 3 types available: galvanized, anodized aluminum, and stainless steel.

The connection of all construction elements is easily and simply achieved with grade 8.8 bolts, ensuring high durability over time and easy disassembly.

Single Pole Mounting Structure

The single pole mounting structure is the most common solution, providing stability and quick installation. It is possible to install panels of all dimensions by adjusting the length of the inclined beam for both portrait and landscape orientation.

The tilt angle is determined by the customer (usually 20, 25, or 30 degrees). Additionally, the height of the anchors can be adjusted to accommodate bifacial panel specifications or to address terrain morphology requirements. Static analysis can also be conducted for terrains with steep slopes in the N-S and E-W directions. It consists of:

- Large support column with a thickness of 3mm, section type P 50x100x3mm

- Small support column with a thickness of 3mm, section type C 50x100x3mm

- Inclined beam with a section type C 100x50x15x3mm

Double Pole Solar Mounting

The double pole solar mounting structure is a different solution, necessary for specific projects. It offers the same advantages as the dual-axis base (installation speed and stability) while being able to accommodate two different configurations:

For single-row panel installations covering all their dimensions, single C120x40x15 profile beams of 3mm thickness and an inclined beam of the same profile with a thickness of 2.5 millimeters are used.

For double-row panel installations (up to 2100mm in height), the structure comprises the following components:

- Reinforced profile beams with a thickness of 4 millimeters (C 160x55x22 profile)

- Inclined beam with a thickness of 3 millimeters (C 14x50x3 profile)

Advantages - WHY CHOOSE US

- Ease of assembly (no welded parts; all components are connected with bolts).

- Ease of transportation as the pieces fit together for greater ergonomics and arrive at the construction site packaged.

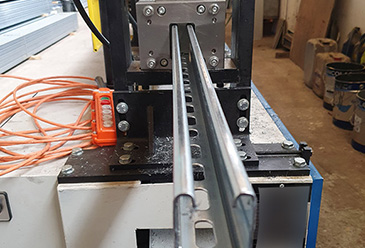

- Capability to fulfill large volume orders in a short timeframe due to an automated production line using high-tech CNC machinery.

- Adaptation of the construction according to the needs and requirements of the project.

In summary, the mounts cover the following support needs:

- Single-row panel single-axis support system

- Single-row panel double-axis support system in portrait orientation

- Dual-axis support system for double-row panels in portrait orientation

- Dual-axis system for bifacial panels

- Dual-axis system for 3 or 4 rows of horizontal (landscape) panels

STRUCTURAL ANALYSIS:

The bases are accompanied by a structural analysis according to Eurocode 1 and 3, as well as the EAK 2003 standards.

- Snow load: 0.80

- kN/m^2 Wind speed: 27 m/s

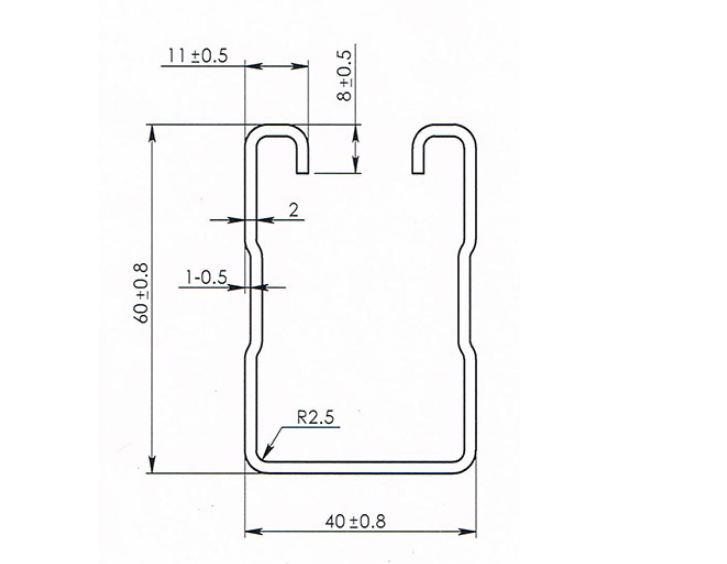

Rails - MAXMETAL

The specially designed MAXMETAL rails stands out in the market. It is a tile ridge with EU Registered Design No 008729073-0001, exclusively developed and produced by our company.

It represents the most robust solution due to the folding of the wings and the reinforcement at the core’s height. Perforated throughout its length for easy and fast installation.

They are manufactured in any length required by the project and can be installed on any base and tiled roof.

Material: S320 Z275

TRANSPORTATION AND ASSEMBLY

Regardless of the chosen system, the transportation of individual pieces is carried out in the most ergonomic manner. All pieces are designed to fit together to reduce volume and transportation costs.

Multi-piece bundles arrive at the construction site promptly, swiftly, and with minimal burden. Quick assembly is another advantage of MAXMETAL bases. They are 100% prefabricated in the factory and delivered precisely on time to the installation site.

The significant advantage of our base is that each frame-triangle consists of single-piece anchors and inclined beams, which are bolted together with only 4 screws, saving installation time and reducing the number of required workforce.